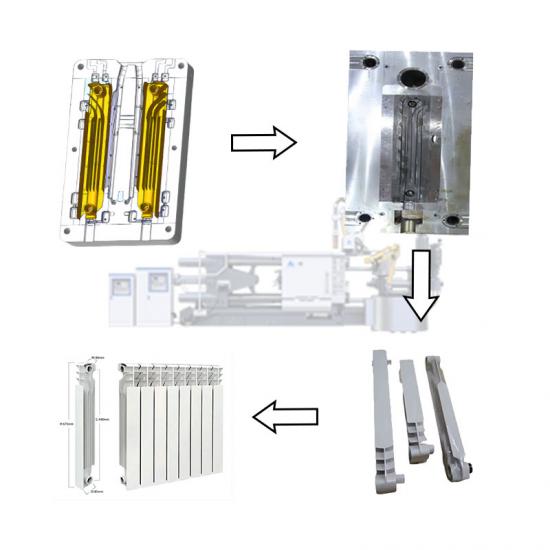

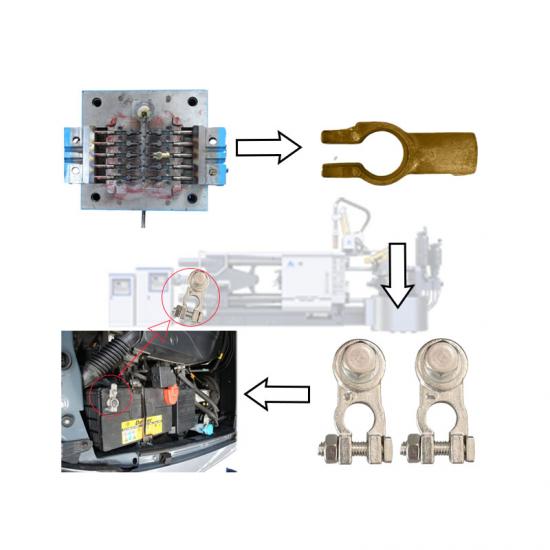

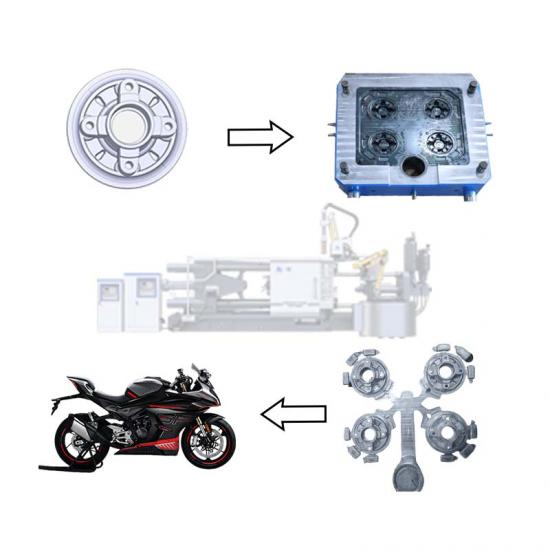

The density of aluminum alloy die castings is relatively small, and it has the characteristics of high strength, strong toughness and light specific gravity. Therefore, under the same structural area, the weight of structural parts can be reduced, so aluminum alloy die-casting parts are widely used in many machines and some precision small parts. The surface gloss of aluminum alloy is brighter than that of ordinary metals, and it has good corrosion resistance in the atmosphere and fresh water, so it has a wide range of uses in the manufacture of civil utensils. Aluminum alloy die-casting parts have good thermal conductivity and electrical conductivity. They are also suitable for use in heat exchange devices used in chemical production and parts that require good thermal conductivity in power machinery, such as cylinder heads and pistons of internal combustion engines. alloy to manufacture.

Due to the large solidification latent heat of aluminum alloy, under the same weight conditions, the solidification process of aluminum liquid lasts much longer than cast steel and cast iron, and has good fluidity, which is beneficial to casting thin-walled and complex-structured castings.

Aluminum alloy die castings not only have the characteristics of high strength, strong toughness, light specific gravity and texture of metal, but also have the characteristics of light weight of plastic and diversified surface technology. Therefore, aluminum alloy die castings are widely used in various fields. For example, it is widely used in door bath hardware, banking, aviation, electronic products, ships, building materials, home appliances, various vehicles and instrument industries. The following Nanhai Fengyi Hardware will explain to you the following advantages of aluminum alloy die castings:

1. Aluminum alloy is conductive;

2. Aluminum alloy has high fluidity, which can fill the mold at the fastest speed during die casting;

3. L'alliage d'aluminium a les caractéristiques d'une haute résistance, d'une forte ténacité et d'une gravité spécifique légère;

4. L'alliage d'aluminium a une forte viscosité et il est facile de coller au moule pendant le moulage sous pression.

5. L'alliage d'aluminium a une forte résistance à la corrosion et à l'usure;

6. La densité de l'alliage d'aluminium est relativement faible. Pour des produits de même volume, la qualité de l'alliage d'aluminium est relativement légère, il présente donc les caractéristiques d'un prix inférieur à celui des autres alliages.